How Does Airgap Affect the Holding Force of a Magnet?

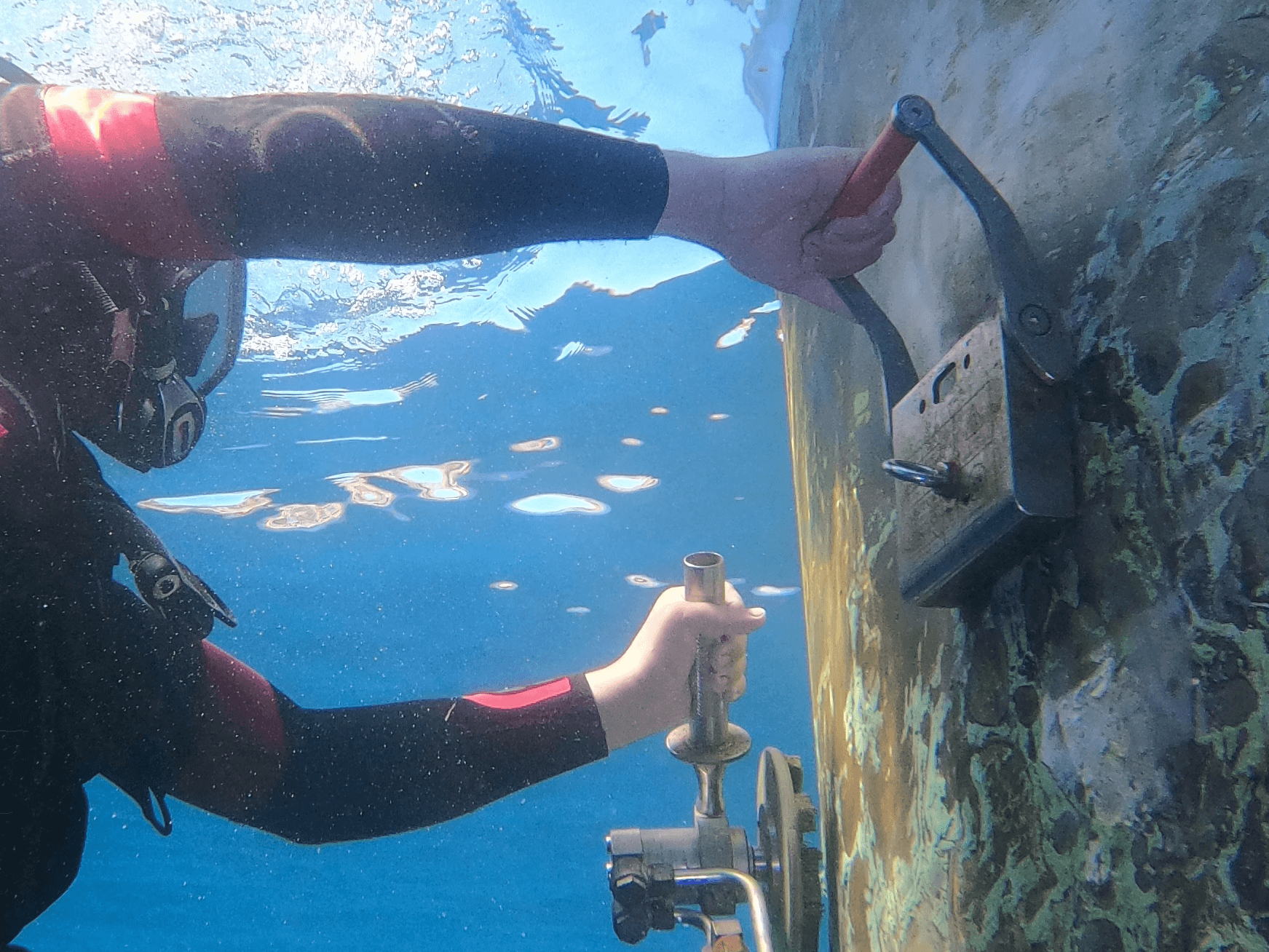

When working with magnets in marine or subsea environments, you rarely get a perfect, lab-grade surface. There may be painted hulls, corroded beams, curved pipes, marine growth, or simply rough or uneven steel. All of these introduce what's commonly referred to as airgap — any form of material or space that separates the magnet from the steel surface and reduces the holding force of the magnet. This is why sandwich magnets, which are less sensitive to airgap than pot magnets, are the wiser choice for divers and ROV operators.

The Physics of Magnetic Force and Distance

The pull force of a magnet comes from it's magnetic field. The stronger the magnetic field, the stronger the force. The field is concentrated close to the magnet, and decreases rapidly in strength as you move away from it. The strength reduces by the cube of the distance, or in mathematical terms:

Where B is the field strength (measured in Tesla or Gauss) and r is the distance.

On top of that, the force is not directly proportional to the field strength, but to the square of the field strength:

Where F is the magnetic pull force. This means that the force drops with the distance to the power of six, or mathematically speaking:

Luckily, in real-world applications it looks a lot better than that. That's because the mathematical conditions above only apply for a very small magnet (a so-called ideal dipole), or far away from a magnet, where the geometry of the magnet itself does not shape the field locally. While it's true that all magnets are sensitive to airgap, there are important differences between various types of magnets due to their different shapes and configurations. Specifically, "sandwich magnets" such as those you can get from us at Blumags outperform the more common "pot magnets" in terms of their ability to overcome airgaps.

Pot Magnets: Cheap, but Sensitive to Airgap

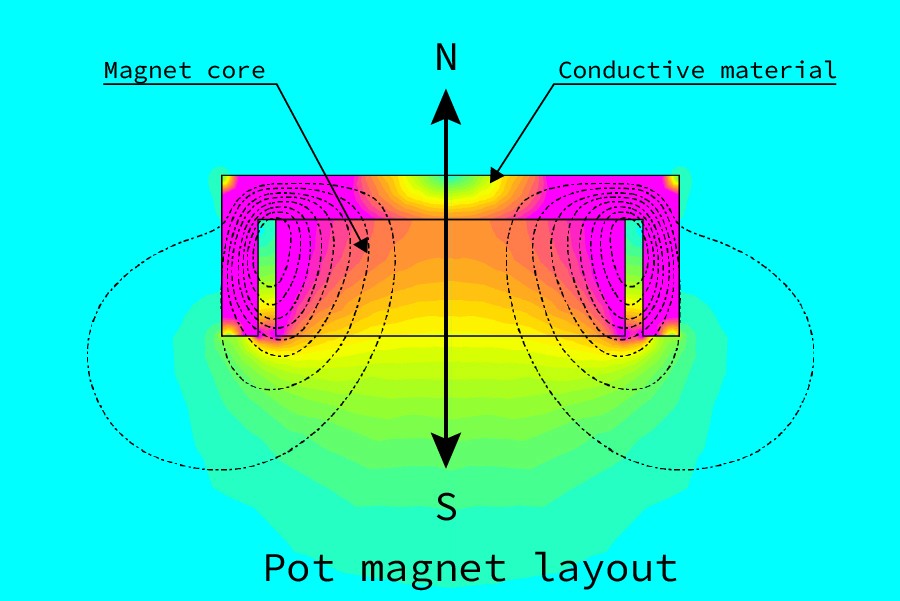

Pot magnets are a common and inexpensive magnet type. They are usually round and consist of a central magnetic core placed inside a steel casing (the pot). They work by forming a magnetic circuit between the pot and the central magnetic core. The core is magnetized vertically, with north and south at the top and bottom. The pot is in direct contact with the top of the core, but (crucially) not the sides of it. It conducts the magnetic field back down to the bottom. The rim of the casing then becomes one magnetic pole, while the core is the other. The only thing that separates the two is the tiny gap that's built in between the casing and the sides of the core. This tight circuit design makes pot magnets very efficient — in ideal, airgap-free conditions.

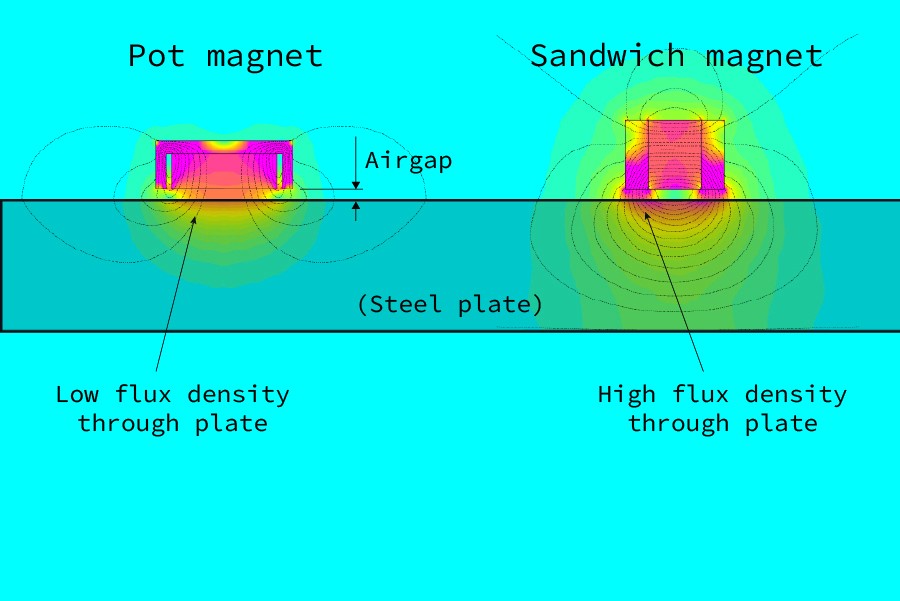

However, that same tight circuit is exactly why pot magnets are extremely sensitive to any separation. The magnetic field is highly concentrated between the rim and the core, and it doesn’t extend far beyond the face of the magnet. The attraction occurs when the magnetic field lines pass through the steel plate. But with just a fraction of a millimeter distance to the steel plate, the magnetic field takes the "shortcut" directly from the rim to the core and skips the steel plate, causing the holding force to drop off dramatically.

Pot magnet: Highly concentrated flux between the rim and the core

Sandwich Magnets: The Wise Choice for Real-Life Conditions

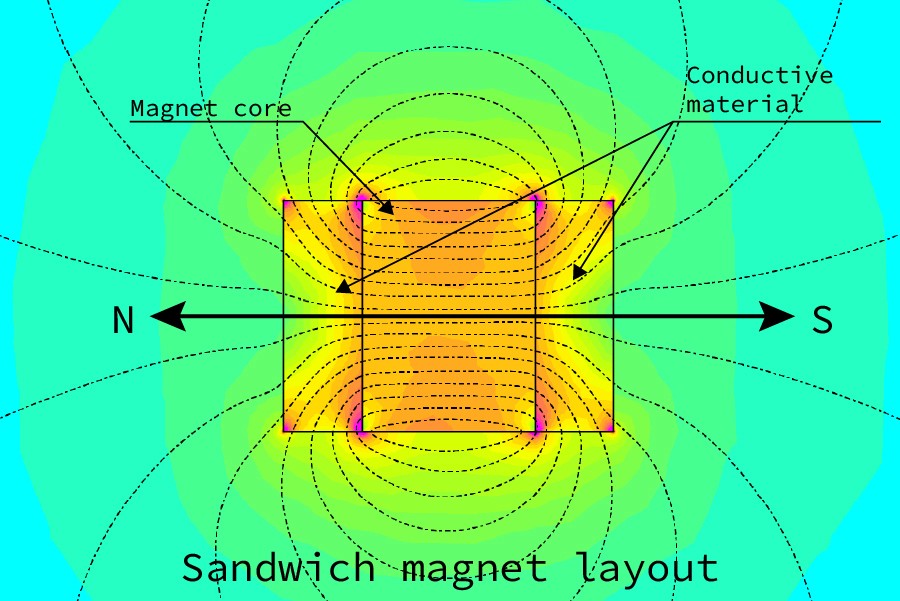

In contrast, sandwich magnets are usually rectangular, consisting of steel plates on opposite sides of the magnetic material. The magnetic elements are magnetized towards each steel plate, so that the two opposing steel elements serve as north and south poles, respectively. A complete sandwich assembly may consist of a repeating pattern: Steel - magnet - steel - magnet - steel, and so on. This configuration creates a more widespread magnetic field that extends further from the magnet surface than that of a pot magnet.

Sandwich magnet: Widespread magnetic field

That means sandwich magnets are inherently more tolerant of airgaps. Even if there’s paint, corrosion, or some marine fouling, the magnet can still maintain a usable field strength and holding force. That’s why all magnets by Blumags are sandwich-type designs — because subsea constructions, ship hulls, or any other steel surfaces encountered by divers or ROV operators rarely consist of bare, perfectly flat and smooth steel.

Comparison between a pot magnet and a sandwich magnet when placed above a steel plate with airgap

What Can Be Done to Minimize Airgap?

Even though sandwich magnets are more forgiving than pot magnets, minimizing airgap is still key to getting the best performance.

Wipe away marine growth or debris

Scrape off loose paint or corrosion where possible

Aim for flat, direct contact when placing the magnet

These simple steps can dramatically improve pull force and reduce the risk of slippage or failure in critical applications.

Expert Help and a Magnetic Performance Tool

At Blumags, we combine deep theoretical knowledge with hands-on experience. We understand how real-world variables like paint, corrosion, and curvature affect performance, and we design our magnets to meet those challenges head-on. If you're unsure how a magnet will perform in your specific application, try our Magnet Calculator. Just enter your actual parameters — including airgap — and we’ll estimate the holding force so you can plan with confidence. And if you need expert advice, contact us at any time.

Author

Lars Lind

Co-founder of Blumags

Share this article: