At Blumags, we don’t believe in off-the-shelf limitations. Every underwater operation is different — which is why each of our magnets is built not just to perform, but to adapt. From lightweight magnetic feet for underwater robots to robust ROV handles and tool mounts, our magnetic solutions are designed for endless customization. Whether you need a ready-to-go setup or prefer to build your own, Blumags gives you the flexibility to do it your way.

Built for Modularity from the Start

Flipper, Willy, and Moby — every model in the Blumags lineup is designed with modularity in mind:

Flipper Series

Our most compact magnet comes with a removable D-bar. Once dismounted, it reveals two M6 threaded holes, ready to accommodate whatever fixture or tool your setup requires — from cameras and sensors to robotic mounts.Willy Series

The Willy 500 features a central M8 clearance hole and two additional M8 holes for mounting — three in total. On the Willy 800, the central hole is upgraded to M10, making it suitable for more demanding integrations.Moby

This heavy-duty model features a large top plate covered in M6 clearance holes, offering a truly flexible platform for mounting complex tools, frames, or custom components.

Magnetic Feet for an Underwater Inspection Machine

We recently delivered a set of Flipper 100 magnets configured to serve as magnetic feet for an inspection machine deployed by ROVs. The client needed a central M10 threaded hole, so we created and supplied custom adapter plates tailored to that spec. It’s a perfect example of how even the smallest magnet by Blumags can be adapted for high-value engineering use.

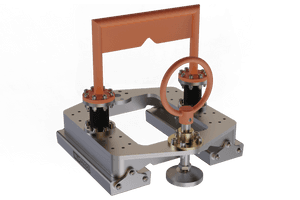

ROV-Ready Willy 800 with Fishtails and Monkey Fists

Another customer needed a Willy 800 configuration suitable for ROV handling. Instead of the standard M10 eye nut, we mounted flex joints with fishtail handles — a widely used ROV grip type. The flex joints absorb mechanical stress, protecting both the magnet and the vehicle. For easier ROV manipulation, we also added monkey fists to the release handles — a thoughtful detail with practical benefits.

Field Use: Underwater Drill Mount

Our magnets also play a key role in field operations. In this video, a customer uses a Willy 800 to secure an underwater drill while repairing a crack. The magnet holds the tool steady, enabling precise work in challenging conditions.

Ready to Build Your Own?

Whether you're customizing for an ROV, a diver-operated tool, or a robotics system, the modular design of magnets by Blumags makes it easy. We can deliver complete packages with adapter plates, joints, and accessories — or simply provide the foundation so you can design the rest.

Need a custom setup? Let’s make it happen.

Contact us to discuss your application.

Jun 2, 2025

Author

Lars Lind

Co-founder of Blumags

Share this article: